Diesel engines are indispensable across numerous industries, yet controlling their harmful emissions is a global priority. Central to effective exhaust purification is the aftertreatment diesel oxidation catalyst (DOC) system, specifically the DOC diesel oxidation catalyst itself. This essential component transforms pollutants into less damaging substances before they exit the tailpipe, forming a foundational element of modern emission control.

The Honeycomb Ceramic Advantage in DOC Technology

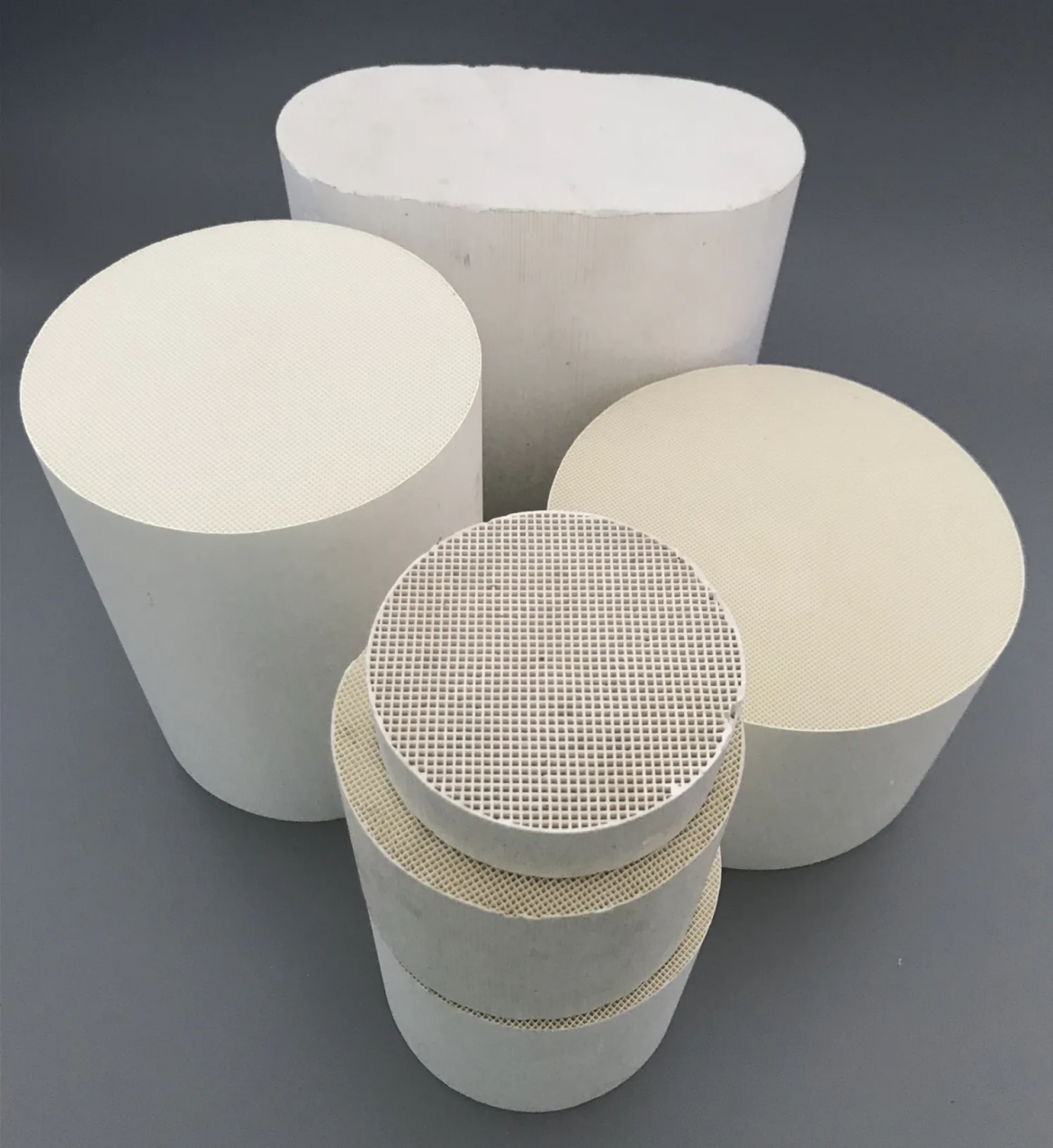

The core of a high-performance DOC diesel oxidation catalyst lies in its robust honeycomb ceramic substrate. This structure, expertly engineered by manufacturers like Hualian Catalyst, provides the ideal balance of characteristics. It offers an immense surface area for critical catalytic reactions while maintaining exceptionally low backpressure. The durability and precision of this ceramic structure are paramount for consistent long-term performance in demanding diesel applications.

How the DOC Catalyst Transforms Exhaust Pollutants

Positioned within the aftertreatment diesel oxidation catalyst system, the DOC diesel oxidation catalyst actively targets gaseous and particulate pollutants. As exhaust gases flow through the honeycomb channels, precious metal coatings catalyze vital oxidation reactions. Carbon monoxide (CO) is converted to carbon dioxide (CO₂), while hydrocarbons (HC) and soluble organic fractions (SOF) are oxidized into carbon dioxide (CO₂) and water (H₂O). This process achieves significant reductions in key harmful emissions directly within the exhaust stream.

Performance Benefits for Demanding Applications

Hualian Catalyst designs its DOC diesel oxidation catalyst solutions to deliver exceptional performance crucial for industrial and vehicular use. These catalysts exhibit excellent thermal stability to withstand the high temperatures inherent in diesel exhaust systems. Combined with high catalytic activity, they ensure efficient pollutant conversion even under challenging operating conditions. Furthermore, the optimized honeycomb design ensures a low pressure drop, minimizing engine backpressure and contributing to better overall fuel efficiency.

Conclusion

To meet strict environmental laws, it is essential to implement a reliable DOC diesel oxidation catalyst system as part of a robust aftertreatment system. Various applications, such as construction equipment, heavy-duty trucks, and non-road machinery, rely on Hualian Catalyst‘s sophisticated honeycomb ceramic DOCs to meet stringent global requirements like EPA Tier 4 and Euro III-VI. Working with a seasoned manufacturer such as Hualian Catalyst guarantees compliance with regulations, improved operational efficiency, and a commitment to environmental responsibility.