In the rapidly evolving field of industrial manufacturing, precision and efficiency are essential for producing high-quality products at scale. The industrial SLA 3D printer has become an invaluable tool for enhancing the stability and durability of equipment, with UnionTech leading the way in this innovative technology. By utilizing cutting-edge digital solutions, this industrial-sized 3D printer is designed to meet the demanding needs of industries such as automotive, aerospace, and heavy machinery. The ability to create intricate, high-precision parts is crucial for improving overall equipment performance and operational efficiency.

Enhancing Manufacturing Precision

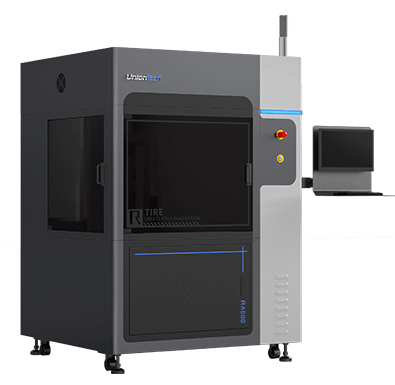

With an industrial SLA 3D printer, manufacturers can create parts with exceptional detail and accuracy, which contributes significantly to equipment stability. UnionTech, an established industrial 3D printer manufacturer, offers models like the RA600, which are specifically designed to meet the needs of industries that require high precision, such as tire mold manufacturing. The RA600 can reproduce complex patterns with a remarkable precision of ±0.1 mm, ensuring that parts are made to exact specifications. This level of accuracy reduces the risk of component failure, increasing the longevity and stability of the equipment.

Reducing Production Lead Time and Costs

A key advantage of using UnionTech’s industrial-sized 3D printer is the substantial reduction in lead time and manufacturing costs. Traditional molding processes can be time-consuming and expensive, often requiring multiple iterations to perfect. With 3D printing technology, companies can produce high-quality molds faster and at a lower cost, eliminating the need for expensive tooling and reducing material waste. This leads to more stable equipment, as parts are produced quickly and with fewer defects, contributing to smoother operations.

Streamlining the Manufacturing Process

The introduction of industrial SLA 3D printers has also streamlined the manufacturing process by allowing for digital tire mold production, as seen with the RA600. With its ability to produce intricate designs with high accuracy, this technology enables faster turnaround times, which is especially important in industries where product availability and speed are crucial. By optimizing the production process, manufacturers are able to maintain better equipment performance and operational stability, which is vital for maintaining competitive advantage.

Conclusion

The industrial SLA 3D printer from UnionTech offers numerous advantages for improving the stability and efficiency of equipment in various industries. By providing unparalleled precision, reducing lead times, and optimizing production costs, these printers play a key role in enhancing equipment stability. As more industries adopt 3D printing technology, UnionTech’s commitment to innovation ensures that manufacturers have access to the tools they need to succeed in today’s competitive market.