Manufacturing leaders today face a relentless cycle of challenges, from the rising costs of raw materials to a critical shortage of skilled technical labor. While digital transformation is often cited as the solution, the gap between theory and practical implementation remains a major hurdle for many facilities. Attending a dedicated metalworking expo serves as more than just a networking opportunity; it acts as a strategic environment for solving real-world production inefficiencies through direct access to innovation.

By bringing together leading equipment manufacturers and process engineers, these events allow decision-makers to test-drive solutions that redefine their bottom line. For those targeting the Asian manufacturing hub, ITES China has become a primary destination to address operational pain points through hands-on experience and direct sourcing.

Optimizing Precision and Reducing Rejection Rates

A recurring struggle in precision engineering is maintaining consistency across high-volume batches. Traditional setups often suffer from mechanical wear or manual alignment errors that lead to costly scrap. At a premier metalwork trade show, the focus is squarely on eliminating these variances through advanced hardware.

Visitors can engage with the latest closed-loop CNC systems and high-precision tooling solutions that guarantee micron-level repeatability. By observing how integrated sensors monitor tool wear in real-time, production managers can transition from reactive repairs to predictive maintenance. Seeing these systems operate under factory-like conditions provides the technical assurance needed before committing to a significant technology shift.

Tackling Material Waste with Advanced Cutting Solutions

In sheet metal fabrication, even a small improvement in material utilization can translate to thousands of dollars in annual savings. Many factories continue to use older thermal cutting methods that result in wide kerfs or significant dross, requiring extensive post-processing.

A professional metalworking expo highlights the evolution of high-power fiber lasers and waterjet technology. Leading exhibitors at ITES China showcase machines capable of intricate nesting and ultra-fast piercing, which minimize both material waste and energy consumption. This direct comparison of cutting speeds and edge quality helps manufacturers identify which equipment will best reduce secondary finishing requirements, thereby shortening the overall production cycle.

Addressing the Labor Gap Through Intelligent Automation

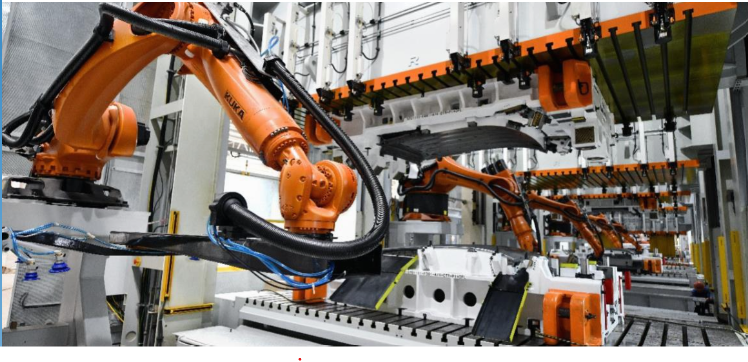

The shortage of specialized personnel in sectors like welding and precision polishing is a global concern. For many businesses, the bottleneck isn’t a lack of orders, but the inability to find the staff to fulfill them. Metalwork trade shows provide a roadmap for automation that does not necessarily require a complete factory overhaul.

From collaborative robots (cobots) that work alongside human operators to fully automated bending cells, these events demonstrate how modular automation can be integrated into existing lines. By exploring the robotics and automation pavilions at ITES China, attendees can find specialized end-effectors and software interfaces designed for rapid deployment. These tools allow factories to scale up output without a proportional increase in headcount or complex retraining.

Strategic Sourcing via ITES China

As a benchmark event for the industry, ITES China is structured specifically to facilitate these breakthroughs. Spanning across the massive Shenzhen World Exhibition & Convention Center, it serves as an integration of the entire supply chain.

The exhibition is divided into specialized sections to help attendees navigate their specific needs:

- Metal Cutting Equipment: Featuring top-tier brands focusing on high-end machining for the aerospace and medical industries.

- Metal Forming & Laser Processing: Dedicated to sheet metal automation and smart welding solutions.

- Precision Manufacturing: A specialized hall for sourcing high-quality non-standard parts, molds, and surface treatments.

Turning Operational Obstacles into Competitive Advantages

The transition from a traditional workshop to a high-efficiency facility requires more than just new hardware; it requires a shift in perspective. A high-level metalworking expo provides the necessary environment to see, touch, and verify the technologies that will define the next decade of manufacturing.

By leveraging the insights and vendor relationships found at ITES China, companies can move beyond simply managing production issues to actively outperforming their competitors. Attending such a comprehensive event ensures that your factory is equipped not just to survive the current industrial shift, but to lead it.