In power generation facilities, maintaining optimal water flow is a delicate balance between energy efficiency and system reliability. Large-diameter pipelines, especially in cooling systems, require valves that can regulate flow without introducing unnecessary resistance. This is where the choice of valve design becomes a critical engineering decision.

The Function of Butterfly Valves in Cooling Applications

Butterfly valves have long been favored in low-pressure, large-diameter water systems because of their compact structure, lightweight design, and quick operation. Their disc-shaped closure mechanism allows for minimal obstruction when fully open, promoting smooth water passage. In cooling water circuits, where rapid flow control is essential to prevent overheating or inefficiency, the butterfly valve’s fast actuation and low maintenance demands make it an attractive solution.

Neway’s Role in Meeting Power Industry Needs

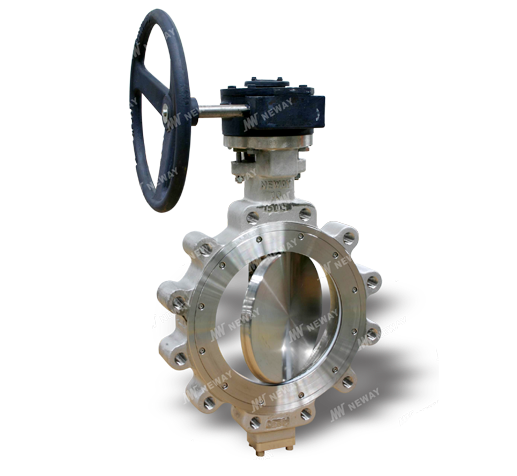

While many manufacturers offer butterfly valves, the Neway butterfly valve line addresses both standard and demanding applications. From concentric designs suited for low-temperature cooling systems to triple offset models capable of handling higher relative temperatures, Neway ensures flexibility in operation. In large-scale power plants, a Neway butterfly valve can provide the right combination of durability and performance, helping operators maintain cooling efficiency without frequent downtime. This adaptability allows facilities to meet varying operational requirements while keeping maintenance intervals manageable.

Conclusion

Efficient cooling water management is vital to the stability of power generation systems. The principles behind the butterfly valve—simple construction, reliable sealing, and quick actuation—make it a cornerstone of flow control. With solutions like the Neway Valve‘s butterfly valve, engineers can match valve design to system demands, ensuring consistent performance in both standard and high-temperature applications.