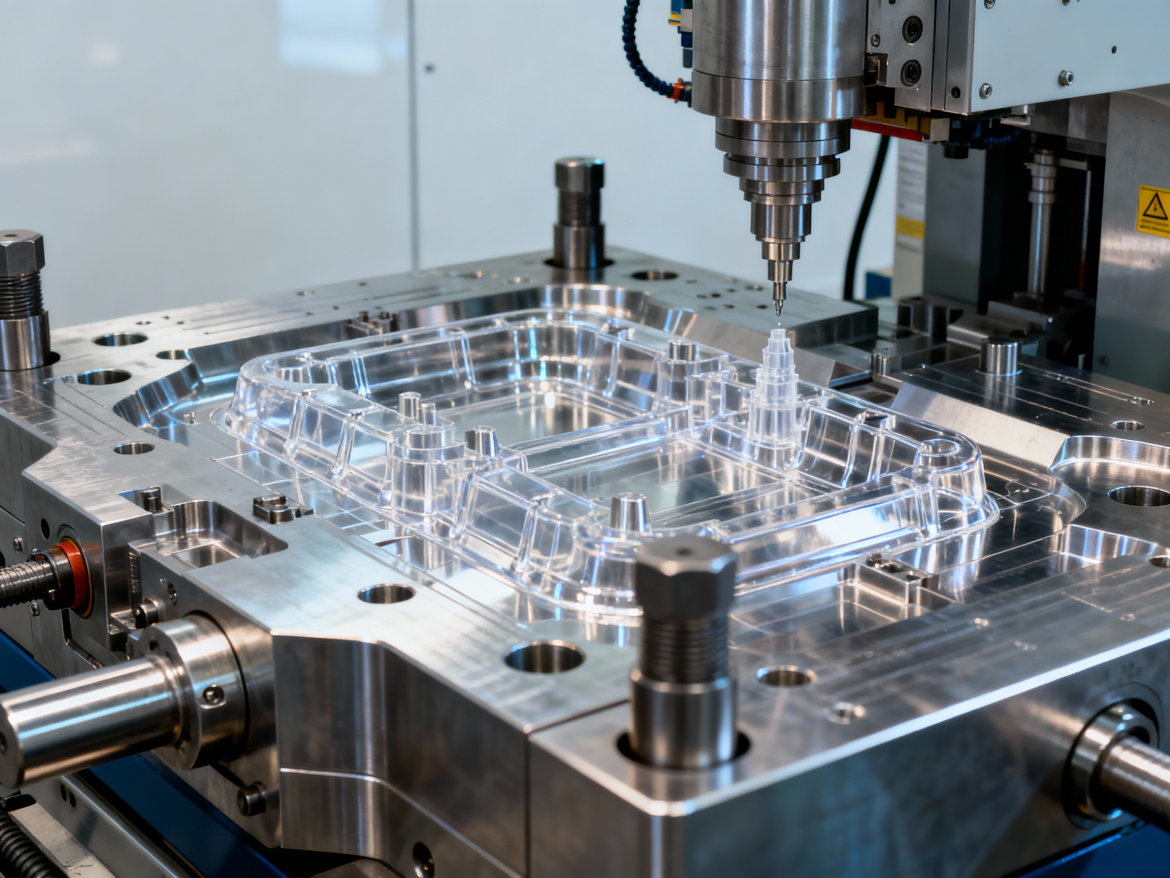

Turnkey plastic injection molding China services are fundamentally reshaping how complex multi-cavity tools are validated for mass production. By shifting from empirical “trial and error” methods to data-driven scientific molding, manufacturers can significantly reduce lead times and material waste. This approach is particularly critical for industries like medical devices and automotive engineering, where part-to-part consistency is non-negotiable. Utilizing decoupled molding strategies—which separate filling, packing, and cooling phases—allows engineers to isolate variables and achieve cavity fill imbalance rates below 5%. This ensures that high-precision parts meet identical specifications across all cavities, streamlining the transition from prototype to volume manufacturing.

Implementing Decoupled Strategies via Precision Plastic Injection Molding China

Decoupled molding breaks the injection process into distinct stages to gain granular control over part formation. This method separates the velocity-controlled filling phase from the pressure-controlled packing phase to eliminate inconsistencies caused by viscosity variations.

Mastering Velocity-Controlled Filling Phases

In the first stage of decoupled molding, the goal is to fill 95% to 98% of the cavity by volume using velocity control alone. This technique relies on the machine’s specific injection speed rather than pressure to move the material. By filling the majority of the part quickly, precision plastic injection molding China facilities prevent the plastic from freezing prematurely, ensuring that the melt front advances uniformly. This approach minimizes the influence of material viscosity changes, which can vary by batch. Engineers set pressure drop limits, ensuring pressure loss remains below 20% of the machine’s capacity, guaranteeing sufficient hydraulic power is available to complete the fill without hesitation.

Executing Scientific Sampling Protocols

To validate the process window, engineers perform rigorous scientific sampling, starting with In-Mold Viscosity Curve studies. By plotting viscosity against shear rate, technicians identify the stable region where viscosity is least sensitive to speed changes. Subsequently, gate freeze studies are conducted to determine the exact seal time. This involves weighing parts at different hold times to pinpoint when the gate solidifies, preventing backflow. A robust process requires controlling gate freeze variation within ±1 second. This data-driven validation creates a reliable process window, ensuring that parameters centered for production remain stable even if minor material fluctuations occur.

Quantifying Stability with Strict Industrial Tolerances

Once the process is decoupled, the focus shifts to maintaining stability through quantifiable metrics. Plastic injection molding factories utilize advanced monitoring to ensure that every shot meets strict industrial tolerances for weight and dimension.

Measuring and Minimizing Cavity Fill Imbalance

Achieving rheological balance is essential for multi-cavity tools. While geometric balance ensures runners are the same length, it does not account for shear-induced heating. Scientific molders measure the fill imbalance by weighing parts from each cavity at the transfer position . For general industrial parts, a fill imbalance of <5% is acceptable. However, for high-precision applications like medical connectors, plastic injection molding in China providers target an imbalance of 2% to 3%. By adjusting runner sizes or melt rotation systems based on this data, manufacturers ensure that every cavity fills and packs at the same rate, resulting in identical dimensional properties.

Real-Time Monitoring in Modern Facilities

To maintain shot-to-shot consistency, facilities integrate cavity pressure sensors (such as RJG or Kistler systems) at post-gate and end-of-fill locations. These sensors capture internal pressure curves in real-time, allowing for the automated containment of abnormal shots. If the peak pressure or integral value deviates from the set limit, the machine robotically segregates the parts. This technology correlates pressure data with dimensional accuracy, ensuring that the standard deviation of part weight remains between 0.1% and 0.3% of the total weight. This level of traceability is vital for compliance in automotive and medical sectors.

Livepoint Tooling: Advanced Turnkey Solutions

Livepoint Tooling stands as a premier provider of plastic injection molding service China, delivering comprehensive solutions backed by over 23 years of expertise. Specializing in high-precision manufacturing, Livepoint offers a strategic advantage for global clients in the automotive, medical, and consumer electronics sectors.

Key Capabilities and Highlights:

Certified Quality Systems: Operating under ISO 9001 and IATF 16949 certifications, Livepoint ensures rigorous quality control suitable for Tier 1 automotive suppliers (serving brands like Tesla and Volkswagen) and medical device manufacturers.

Complex Tooling Expertise: The company excels in unscrewing plastic injection molding China, capable of producing intricate threaded components and complex geometries that require precise core-pulling mechanisms.

Innovation in High-Voltage Insulation: Livepoint demonstrated exceptional engineering capability by partnering with top universities to mass-produce UHV hybrid insulators. They developed proprietary molds and specialized equipment to achieve a >95% yield rate on a project where industry averages were significantly lower.

Comprehensive Traceability: From Incoming Quality Control (IQC) to Final Validation (OPQC), every production batch is documented, providing full traceability for regulated industries.

By leveraging advanced CAE flow analysis and proprietary manufacturing technologies, Livepoint Tooling transforms complex concepts into tangible, high-quality products. For engineers seeking a reliable partner to navigate the complexities of mass production, Livepoint offers the technical depth and operational scale required for success.

Conclusion

Adopting scientific sampling and decoupled parameters is essential for engineers seeking reliable, high-precision molded parts. Partnering with a capable manufacturer like Livepoint Tooling is the first step toward achieving zero-defect production and seamless validation.